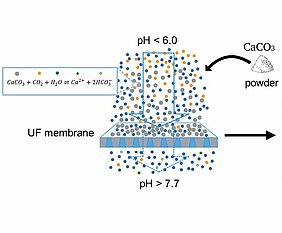

Aim of the project was the evaluation of a new process combination for the deacidification of a soft spring water by dosing powdered calcium carbonate and particle removal by UF. The results showed that this process is a promising alternative to limestone filtration followed by UF.

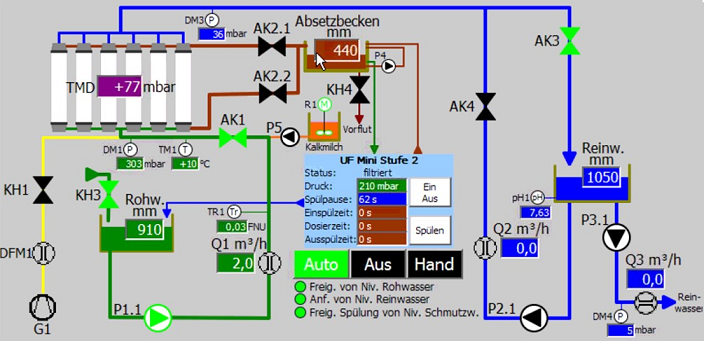

Soft acidic waters are often treated for drinking water purposes by using limestone filters to attain chemical equilibrium. The present study investigated the process parameters of a relatively new process combination in which powdered calcium carbonate (CaCO3) was added prior to an ultrafiltration (UF). The process is designed as a two-step UF filtration, where the backwash water of the first UF step is collected in an intermediate tank and treated by a second UF step. The filtrate of this second UF is returned to the feed of the first UF step. The retention time in the intermediate tank is sufficient such that almost all calcium carbonate dosed into the feed is able to dissolve. In order to reach the target pH-value of >7.7 the operation conditions had to be adapted. During the research project the dosing concentration, the type of material and the required retention time were evaluated in pilot-scale experiments. The deacidification followed the same kinetics as for limestone filtration and reached similar filtrate characteristics with dosing concentrations of 20 g/L and 40 g/L CaCO3. The overdosing of the calcium carbonate material resulted in higher calcium and bicarbonate concentrations than desired. Therefore, dosing concentration has to be decreased and a physical deacidification has to be implemented in the process for the large scale application.

During operation of the pilot-scale UF module no significant increase in transmembrane pressure was observed at low flux (34 L/m²/h). Critical flux was determined in lab-scale to evaluate the potential impact of CaCO3 particles on the UF operation. Stepping-flux experiments revealed the presence of fouling only at high dosing concentrations, resulting in a critical flux of 55 L/m²/h. At higher flux a CaCO3-fouling layer was formed, that decreased the membrane’s permeability by 20% over five hours. Considering that effective air-enhanced backwash and acidic chemical cleanings will be implemented in large-scale applications, the investigated process combination promises to be an appropriate treatment technology for turbid and soft acidic waters.

Publications

Lipp, P.: Kompakte Entsäuerung mittels CaCO3 in Kombination mit Ultrafiltration“. Veröffentlichungen aus dem Technologiezentrum Wasser 95, ISSN 1434-5765, 81-95 (2020).

Morales, Y. G.; Lipp, P.: Deacidification through calcium carbonate dosing in combination with ultrafiltration. AQUA - Water Infrastructure, Ecosystems and Society Vol 70 No 8, 1111-1120 (2021). DOI: 10.2166/aqua.2021.030.

![[Translate to English:] Prüfstelle-Produktprüfung_Teststand Test centre and product testing](/fileadmin/_processed_/0/9/csm_TZW-Karlsruhe_Pruefung_Geraete-Teststand_377188946c.jpg)