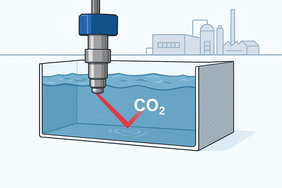

Widely tunable MIR lasers for real‑time inline CO₂ measurement in waterworks – enabling optimized process control, plant operation, and resource efficiency in water treatment.

In many industrial sectors, production monitoring is currently carried out using offline analyses, in which samples are taken and examined in the laboratory. As a result, these processes cannot be controlled in a resource‑efficient, real‑time manner. Using applications in the pharmaceutical sector and in drinking water treatment as examples, the project aims to demonstrate the potential of mid‑infrared laser sensing for inline analyses, along with the corresponding resource savings.

The widely tunable MIR laser to be developed within the project will enable automated inline process control and quality monitoring in drinking water treatment.

The objective of the present subproject, conducted by TZW, is to validate the laser in the TZW technical center as well as on‑site in waterworks.

Online measurement of dissolved free CO₂ in water allows for more precise and immediate control of CO₂ dosing or degassing systems. This is particularly relevant for the protection of reverse osmosis (RO) systems, which are operated in waterworks for partial softening.

In RO systems, controlled CO₂ dosing can prevent scaling on the RO membranes.

Furthermore, CO₂ measurement supports the adjustment of the lime–carbonic acid equilibrium, especially when raw water quality fluctuates, for example due to the mixing of different water sources. A control strategy based on continuous CO₂ measurement has a positive impact on both chemical and energy consumption.

The InlineMIR project includes Stadtwerke Gaggenau (SWG) and Trinkwasserversorgung Würzburg GmbH (TWV) as associated partners.

![[Translate to English:] Prüfstelle-Produktprüfung_Teststand Test centre and product testing](/fileadmin/_processed_/0/9/csm_TZW-Karlsruhe_Pruefung_Geraete-Teststand_377188946c.jpg)