Industrial process waters containing high levels of salt should be recycled in chlorine-alkali electrolysis after purification and enrichment steps. TZW has supported quality assurance and has helped to evaluate the treatment processes in the joint project by conducting organic trace analyses.

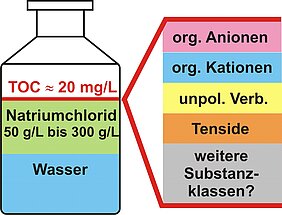

Discharging process waters with high levels of neutral salts from industrial synthesis in the environment is a form of water pollution. The aim of the ReSalt project was to recover the NaCl from industrial wastewaters and to recirculate it in chlorine-alkali electrolysis as well as to reuse the purified water. The concept developed in the project had the aim of improving inter-company collaboration and general resource efficiency as well as to prevent substances from entering the natural water cycle and the reduction of the primary water demand in industrial processes.

The TZW sub-project has provided information on the organic impurities contained in the process waters. Various sample preparation techniques (e.g., solid phase extraction, liquid-liquid extraction, distillation, derivatisation, ion exchange) were tested on their suitability to separate and enrich organic compounds from the salt matrix. In addition to the development of a method for known organic impurities in wastewater, non-target screening was used to discover other currently unknown components. GC-, RP- and IC-separation methods were combined with various detectors (LF, UV, ESI-MS/MS, ESI-qTOF). An automated SPE-IC-CD method was developed that can serve as a basis of a process analyzer applied in industrial processes.

In cooperation with UNISENSOR Sensorsysteme GmbH, the WATERTRACE sensor system has been successfully tested for online analyses of saline process waters. Further application in the field of industrial process analysis is now conceivable.

![[Translate to English:] Prüfstelle-Produktprüfung_Teststand Test centre and product testing](/fileadmin/_processed_/0/9/csm_TZW-Karlsruhe_Pruefung_Geraete-Teststand_377188946c.jpg)