The project aims to develop and test an underwater system for monitoring the condition and location of linear and point infrastructure components.

For the economic operation of drinking water supply, it is essential to renovate and renew water supply facilities based on the condition of the network. To this end, it is essential to have as accurate information as possible about the condition of the facilities. This also includes pipes laid in water bodies, such as culverts in rivers or raw water intake pipes. Since conventional methods that can be used from the earth's surface are generally not applicable in water bodies, investigations are currently not carried out or only with great effort, such as inspection by divers.

Project scope

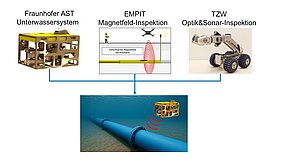

In cooperation between Fraunhofer IOSB-AST, EMPIT and TZW, an innovative underwater inspection system is being developed and tested under real conditions. The system is equipped with several sensors, including a CMI sensor from EMPIT specially modified for underwater use to assess the condition of metallic materials, a sonar and optical sensors.

Fraunhofer IOSB-AST is responsible for developing and providing the carrier platform and the semi-autonomous control system. TZW is responsible for project coordination, planning and implementation of practical applications at water suppliers, evaluation of optical data and assessment of the method with regarding its use in asset management.

Two water suppliers are making their infrastructure available for the practical investigations: a main drinking water pipe laid in the water and a raw water pipe including the associated extraction structure.

System adaptation

An initial preliminary test was conducted to determine whether the transport pipeline was fundamentally suitable for use with the CMI (current magnetometry inspection) method and whether the water body was suitable for investigation with a semi-autonomous underwater inspection device.

The application of the CMI method revealed that the longitudinal conductivity of the pipeline is insufficient to transmit the applied voltage over a sufficient distance. An alternative connection point is therefore required for the successful implementation of the method, as the one originally planned is not suitable.

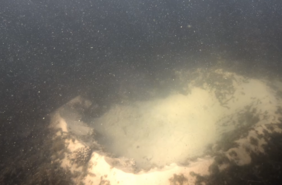

An initial survey of the water body was carried out using the ROV (Remotely Operated Vehicle). The pipe coordinates provided by the water supplier where integrated into the ROV's control software, and the vehicle was manually steered along the route across the bottom of the waterway. It was found that the pipes were covered by a layer of sludge, which meant that neither the camera nor the sonar could detect the outside of the pipe.

Despite limited visibility, GPS navigation enabled the pipe to be traced precisely. This made it possible to identify a leak: the escaping water caused significant turbulence in the sludge at the bottom of the lake. The coordinates of the leak, determined by GPS, were passed on to the water supplier for further processing and repair.

Project partner

EMPIT is a global deep tech company specialising in the inspection and mapping of buried, non-pigged pipelines. With its patented Current Magnetometry Inspection (CMI) technology, EMPIT offers a unique solution for above-ground condition assessment of such pipelines. The company was awarded Germany's most prestigious innovation prize for this innovation.

As a fast-growing, independent company, EMPIT contributes to the safe and sustainable use of ageing infrastructure. Around 50% of today's pipelines are considered inaccessible – EMPIT enables their reliable inspection, thereby protecting facilities, personnel, the public and the environment.

Fraunhofer IOSB-AST in Ilmenau develops seaworthy underwater robotics systems for exploration, inspection and manipulation. The department has many years of experience in the development of autonomous functions and AI-based sensor data evaluation for underwater vehicles used in areas such as offshore wind energy, marine cleaning and aquaculture.

Two remote-controlled ROVs and one autonomous AUV are currently available. Thanks to open interfaces, sensors from project partners can be flexibly integrated – regardless of their stage of development.

TZW (German Water Centre) is a leading non-profit research institution for water quality, safety and technology based in Karlsruhe with a branch office in Dresden. As part of the German Technical and Scientific Association for Gas and Water (DVGW), the TZW is one of the most important centres of expertise for water management in German-speaking countries. Around 200 employees work in interdisciplinary teams on approximately 50 practical research projects each year.

The focus is on raw water and resource protection, microbiology, trace substance analysis, innovative treatment processes, digitalisation, network management and risk assessment. TZW advises water suppliers, authorities and companies and is actively involved in standardisation committees (DIN, CEN, DVGW) and international networks such as GWRC, IWA, WaterEurope and EurEau.

![[Translate to English:] Prüfstelle-Produktprüfung_Teststand Test centre and product testing](/fileadmin/_processed_/0/9/csm_TZW-Karlsruhe_Pruefung_Geraete-Teststand_377188946c.jpg)