The aim of the project was the holistic and systematic investigation of drinking water installations on the lab scale, in pilot plants and in field trials in order to prove the effectiveness of ultrafiltration (UF) while keeping domestic hot water (DHW) installation hygienically safe during operation with reduced temperatures. Furthermore, the effect of UF on the primary energetic impact of the installations was evaluated to determine the potential of CO2 emission reduction.

Based on the current accepted rules of engineering for drinking water hygiene – targeted to Legionella spp. – DHW installation for apartment buildings are required to maintain a temperature of 60 °C at the outlet of the DHW heater and to operate the circulation system at 55 °C minimum. This temperature level makes it difficult to use regenerative heat generators and to implement low temperature district heating grids.

Generally, the separation of microorganisms and nutrients from drinking water appears to be a useful technical approach to avoid microbiological growth and enable operators to run drinking water heating systems with considerably reduced temperatures. UF systems seemed to be a suitable tool to implement this approach within drinking water installations.

The outlined project carried out a systematic, scientific investigation to study the relationship between the concentration of microorganisms and nutrients in the water and Legionella contamination in the system. This concerned not just the effect of the UF systems, but moreover the prevention of back contamination from UF to the DHW installation and the effectiveness of backwashing the filter and safely discharging the wash water.

The results of the now finished project are used to make scientifically based recommendations on the use of ultrafiltration in drinking water installations.The final results are presented on the Berliner Energietage 2024 at the 16th of May in Berlin.

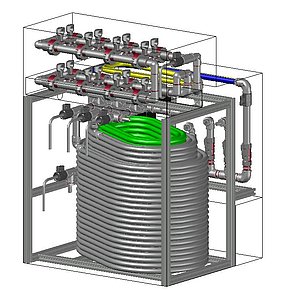

![[Translate to English:] Prüfstelle-Produktprüfung_Teststand Test centre and product testing](/fileadmin/_processed_/0/9/csm_TZW-Karlsruhe_Pruefung_Geraete-Teststand_377188946c.jpg)